Welcome to the TESCO Technical Services (TTS) page. TTS is focused on providing the knowledge, expertise and strategy of Reliability Based Maintenance (RBM) for our customers 24/7/365 by performing:

On-line Vibration Analysis On-line Vibration Analysis

Laser Alignment Laser Alignment

On-site Balancing of Rotating Equipment On-site Balancing of Rotating Equipment

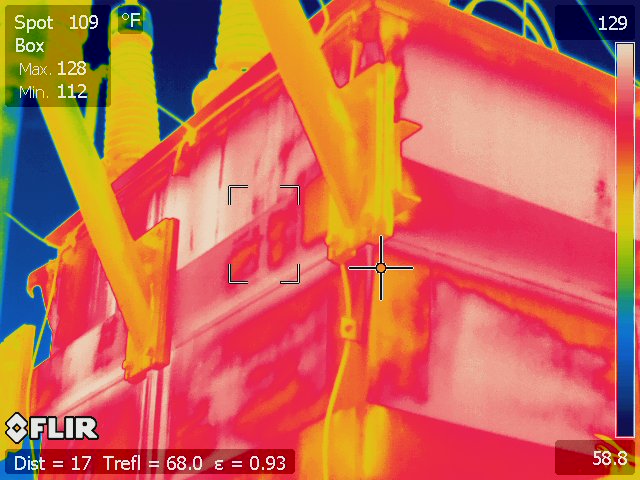

Infrared Thermography Infrared Thermography

Electric Motor “Current Signature Analysis” Electric Motor “Current Signature Analysis”

MCEmax On & Off Line Motor Analysis and Testing MCEmax On & Off Line Motor Analysis and Testing

Training Training

DC Motor Brush Maintenance DC Motor Brush Maintenance

Crane Certification & Load Testing Crane Certification & Load Testing Reliability Based Maintenance (RBM) is a maintenance strategy based on the benefits of Preventive Maintenance (PM), Predictive Maintenance (PdM) and Proactive Maintenance (PaM) in a way that eliminates unexpected equipment failures in the manufacturing arena. (RBM is intended to redirect plant maintenance from being considered a “necessary evil” into being viewed as a positive integral part of the cash flow process.) Utilizing the RBM Systematic Process and working closely with the customer:

We identify each piece of equipment (motors, pumps, gear-cases, etc.) We identify each piece of equipment (motors, pumps, gear-cases, etc.)

Establish the performance criteria for each identified piece of equipment Establish the performance criteria for each identified piece of equipment

Develop a computer based program in which to: Develop a computer based program in which to:

♦ Collect the desired data

♦ Analyze

♦ Produce a report of any issues found listing them as:

• Emergency Action (Immediate shutdown and corrective action

suggested)

• Definite Problem (Suggest scheduling corrective action ASAP)

• Potential Problem (No immediate danger, corrective action

needed)

• Comment (Minor problem may exist) NOTE: All of our technicians are ISO Certified through the “Vibration Institute” (a “Not For Profit Organization”) at a minimum of Level II Certification in Vibration Analysis. Also, all techs have their Laser Alignment Certification.

Diagnostic Test Equipment Utilized: Optilign Smart…Laser Alignment

FLIR ThermoCAM P640…Infrared Thermography

ISI Infrared Solutions Snapshot...Infrared Thermography

CSI 2130 Machinery Health Analyzer (dual channel):

• Advanced Vibration Analysis

• Electric Motor “Current Signature Analysis”

• On-site Dynamic Balancing of Rotating Equipment

PdMA MCEmax Electric Motor Analyzer...IEEE 56™ /Rev.18

• Bar-to-Bar Armature Testing for DC Motors

• Both On-Line and Off-Line Testing

• 250 to 5000 Volts Capability

|